Understanding Diesel Engine Parts and Their Importance

In today's fast-paced industrial landscape, diesel engines play an integral role in powering a wide variety of machinery and vehicles. Their durability and efficiency make them a preferred choice for many operators. To ensure these engines operate at their optimum performance, it is essential to understand the various diesel engine parts and their functions. This guide delves into the critical components that make up a diesel engine, focusing particularly on spare parts and suppliers, especially valves.

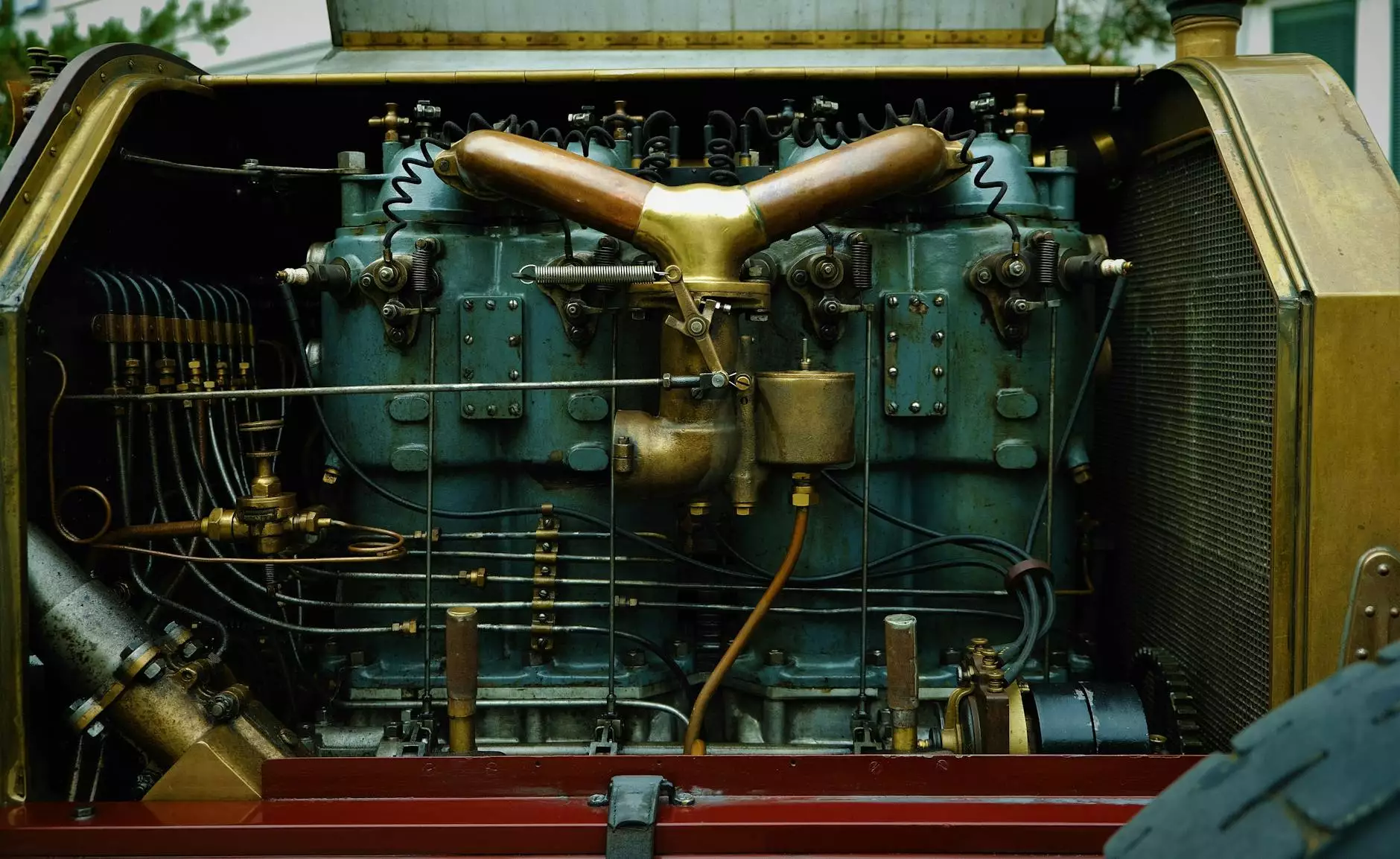

Key Components of Diesel Engines

Diesel engines consist of multiple parts, each serving a unique purpose. Understanding these components is crucial for maintenance and repair, ensuring your engine runs smoothly.

- Engine Block: The core component housing the cylinders and various other parts.

- Cylinders: Where the combustion of fuel takes place.

- Pistons: Move up and down in the cylinders to convert combustion energy into mechanical energy.

- Cylinder Head: Encloses the top of the cylinders and houses the intake and exhaust valves.

- Valves: Control the flow of air and fuel into the cylinders and the exhaust out of them. This is where the valve comes into play.

- Fuel Injectors: Deliver fuel into the combustion chamber under high pressure.

- Turbocharger: Increases engine efficiency and power output by forcing in more air.

The Role of Valves in Diesel Engines

Valves are among the most critical components in a diesel engine. Their primary function is to control the intake of air and fuel and the exhaust of combustion gases. A proper understanding of valve function and maintenance can lead to improved engine performance and longevity.

Types of Valves

There are different types of valves in diesel engines, each serving distinct purposes:

- Intake Valves: Allow air and fuel mixture to enter the combustion chamber.

- Exhaust Valves: Let burnt gases exit the combustion chamber after combustion.

Importance of Quality Valves

Investing in high-quality valves can greatly impact the efficiency and durability of your diesel engine. Poor-quality valves may lead to premature failures, increased emissions, and sub-optimal performance. This emphasizes the need for choosing reputable suppliers when sourcing valves and other diesel engine parts.

Choosing the Right Spare Parts Supplier

Selecting the right supplier for diesel engine parts can be challenging with numerous options available. Here are some essential factors to consider:

- Reputation: Look for suppliers with a strong reputation in the industry and positive reviews.

- Product Quality: Ensure the parts offered meet industry standards and specifications.

- Customer Service: Reliable customer service can significantly enhance your buying experience.

- Range of Products: Opt for suppliers that provide a comprehensive product range, including valves and other critical components.

- Warranty and Return Policy: Good suppliers should offer warranties on their parts to protect your investment.

Benefits of Choosing a Specialized Supplier

Dealing with suppliers that specialize in diesel engine components can yield numerous benefits:

- Expertise: Specialized suppliers have in-depth knowledge and experience in diesel engine parts.

- Technical Support: Access to technical assistance can help in making informed decisions during the purchase.

- Durability: Specialized suppliers tend to offer parts that are more durable and suited for specific engine types.

Maintenance Tips for Diesel Engine Parts

Proper maintenance is crucial for extending the life of your diesel engine and its components, including valves. Here are some helpful tips:

- Regular Inspection: Frequently check components for any signs of wear or damage to catch issues early.

- Cleanliness: Keep the engine and its parts clean to prevent contamination.

- Routine Oil Changes: Regular oil changes ensure the lubrication of moving parts, including valves.

- Use Quality Spare Parts: Always replace worn-out parts with high-quality equivalents to ensure good performance.

The Future of Diesel Engine Parts

As technology evolves, the diesel engine parts industry is also witnessing significant advancements. Innovations such as electronic fuel injection systems and advanced turbocharging technology are paving the way for more efficient and powerful diesel engines.

Furthermore, with an increasing focus on environmental impact, many manufacturers are looking to create more fuel-efficient and less polluting engines. This means that the demand for high-quality, effective diesel engine parts, especially valves, will continue to rise.

Conclusion

Understanding the intricacies of diesel engine components, particularly valves, is essential for anyone involved in the operation or maintenance of diesel engines. By choosing high-quality spare parts from reputable suppliers like client-diesel.com, operators can ensure optimal performance and longevity of their engines.

Investing time and resources in knowledge about diesel engine parts, maintenance, and sourcing methods can drastically improve engine performance and efficiency, leading to greater overall operational success.

https://client-diesel.com/en/products/valve